.jpg?width=2000&name=09_2024_WE_CaseStory_Raumland%2012-2%20(2).jpg)

INTELLIGENCE MADE PHYSICAL

Smart automation that works, adapts, and deploys easily.

Why automation matters

.png)

Empower people

Reduce repetitive and physically demanding work so people can focus on higher-value tasks.

Boost productivity

Increase throughput and consistency without relying on manual work.

Enhance adaptability

Deploy automation that can handle change, not just steady-state production.Automation designed to work in the real world

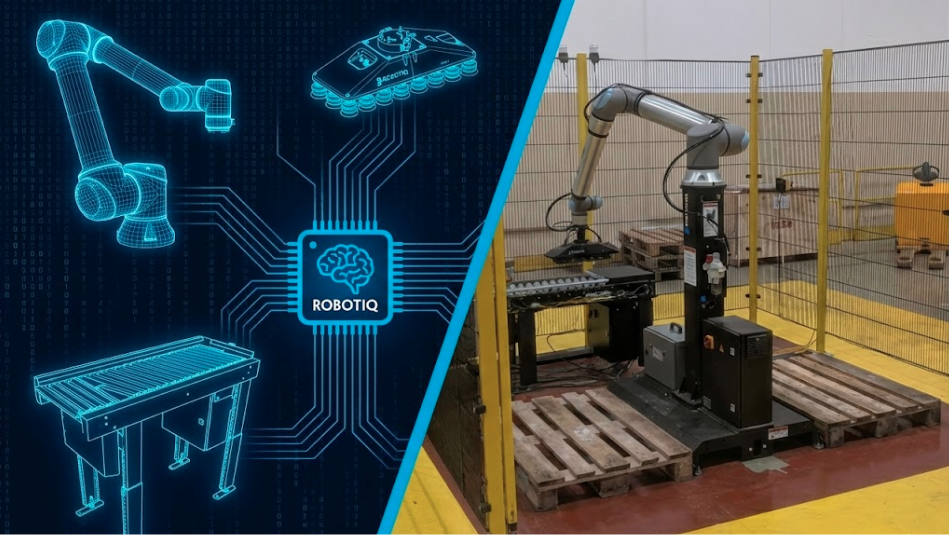

Most automation struggles because integration is complex and custom.

Robotiq simplifies it by embedding intelligence directly into what you deploy, so your automation just works.

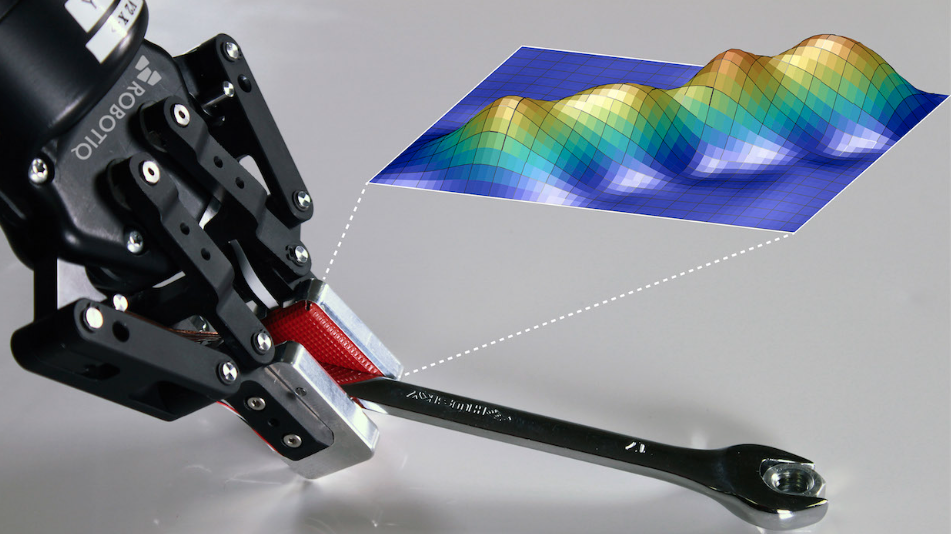

Built-in task intelligence

The intelligence lives inside the systems and components that perform the task, improving reliability, consistency, and performance on the factory floor.

Automating integration

What you can deploy

Workcells

Production-ready solutions designed to deploy quickly and perform predictably.

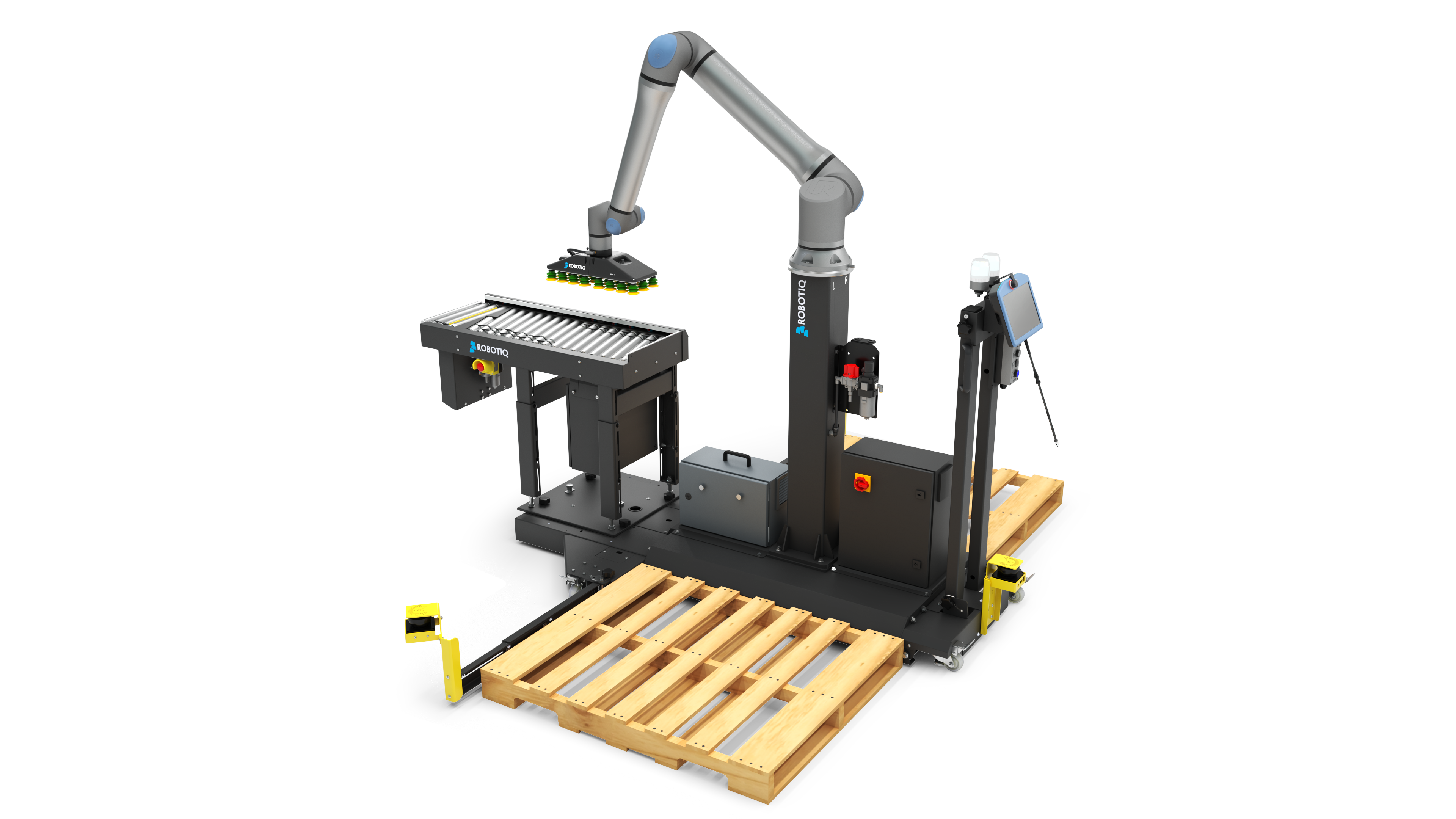

Lean Palletizing

Automate your end-of-line with ease. Robotiq’s Lean Palletizing workcells are fast to install, simple to operate, and ready to scale—boosting productivity, reducing strain, and adapting to every SKU and layout.

More

Machine Tending

Optimize productivity and ensure the continuous operation of your machines with minimal downtime, providing you with peace of mind.

More

Screwdriving

Achieve precision and reliability in every task, simplifying even the most intricate small-screw assembly processes with unmatched efficiency.

MoreComponents

Industrial-grade components with intelligence built in, ready to integrate into your systems.

Vision

Wrist CameraProof from the factories

Tens of thousands of factories worldwide use Robotiq products.

These stories show how manufacturers and system builders turn automation into real results.

Cascade Coffee: When palletizing finally scaled

How Cascade Coffee improved safety, performance, and employee satisfaction with 6 Lean Palletizing workcells.

The ROI was a slam dunk from the beginning, from how much labor it saved. The installation process was the smoothest install of any piece of equipment I have had to experience in 28 years.

Greg Thayer

Vice-President, Cascade

coffee

Sennheiser: Scaling quality testing without slowing production

Sennheiser increased testing throughput by 33% while handling 115 different PCB types—proving that flexible automation can boost quality without adding complexity thanks to Robotiq's 2F-85 Adaptive Gripper.

The cobots are fast, but I can keep up - and it’s great how much we’ve increased our numbers.

Marcella Segovia

PCB Testing Operator, Sennheiser Manufacturing

Glenhaven: Automation at speed

Explore how Glenhaven optimized operations, reduced labor dependency, and set the foundation for continued growth by implementing Lean Palletizing.

The simplicity of the cobot for users was one thing that appealed to me, and how it was user-friendly.

Stephen Murphy

Project Manager, Glenhaven

Deanan Popcorn: Small footprint, big impact.

Discover how Deanan Popcorn scaled up operations without disrupting their layout thanks to a quick installation of a Lean Palletizing workcell.

It doesn't have the big cage around it, and the footprint is so small, like it's half a pallet, and it's movable. Those two things sold me right away. On top of that, it had a third of the budget that all the other robot companies had proposed.

TREF HODGE

Chief Operations Officer, Deanan Gourmet Popcorn

Eckerts GmbH: Automating distillation, safely

Robotiq’s Lean Palletizing workcell empowers Eckerts’ small team, boosts efficiency in handling heavy cartons, and adapts to the distillery’s compact workspace.

This solution is one of the best things we have bought in recent years. The system has been running flawlessly from day one.

Andreas Klemp

Production manager, Eckerts GmbH

Raumland GmbH: Automating heavy wine carton palletizing with safety and efficiency

See how Lean Palletizing workcells now handle over 5M bottles and 2,500 varieties of wine per year, relieving employees of manual labor.

The cobot perfectly reflects what we need. It is a flexible machine, compact, quick to set up, and, ultimately, affordable. We were able to automate a task that was extremely tedious. No one complains about back pain anymore. At least not from palletizing.

Sebastian Raumland

Managing Director, Raumland GmbH

Hack AG: Lean Palletizing for multi-line bakery production

Robotiq Lean Palletizing helps Hack AG handle 800 SKUs across multiple lines, reducing manual labor and fatigue. Fast to move between lines and easy to train on, the palletizer boosts efficiency, flexibility, and employee well-being, with a payback period of just 14–16 months.

The key result for our production process is that we are now further flexible in our processes and product planning, and we decreased the hard work of our employees.

Simon Gunnemann

Managing director central production, Hack AG

-2.png)

1_2026_Siemens_UR_demo_CES2026.gif)